| Model | QF-2000 | QF -2400 | QF -2800 |

| Max.Cardboard | 1000*2000mm | 1000*2400mm | 1200*2400mm |

| Mini.Cardboard | 260*600mm | 300*700mm | 300*700mm |

| Installation area | 2400*13500mm | 2800*15300mm | 2800*15300mm |

| Power Required | 6.5kW | 8.0kW | 8.0kW |

| Design speed | 120 pieces/min | 120 pieces/min | 120 pieces/min |

| working speed | 180 pieces/min | 180 pieces/min | 180 pieces/min |

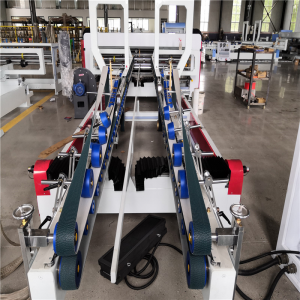

Vacuum suction feeding to feed warping paperboard easily. Quality electromagnetic clutch and brake adopted, feeding section controled independent,operation easily Scorer wheel adjustable, suit for 2-8mm thick paperboard Second creasing struction can impress again the paperboard which was not creased well.Simpless structure and high reliat gue quantity adjustable, cleaning easily Stainless steel glue wheel adopted kong lite and saving glue cost: Imported quality rubber beilt adogted automatic folding With paperboard rectily device and creasing rectity device.Stacking and counting are simple and reliable; Digital control, operation easily and reliable. No-stop put in data and automa *With rectification function. Paperboard counting and put out by pneumatic, stable and quickly.1. PLC controller 2. Touch screen type input data 3. No machine halt change data 4. Automatic paper-feeding, fold, counting, stacking

Vacuum suction feeding to feed warping paperboard easily. Quality electromagnetic clutch and brake adopted, feeding section controled independent,operation easily Scorer wheel adjustable, suit for 2-8mm thick paperboard Second creasing struction can impress again the paperboard which was not creased well.Simpless structure and high reliat gue quantity adjustable, cleaning easily Stainless steel glue wheel adopted kong lite and saving glue cost: Imported quality rubber beilt adogted automatic folding With paperboard rectily device and creasing rectity device.Stacking and counting are simple and reliable; Digital control, operation easily and reliable. No-stop put in data and automa *With rectification function. Paperboard counting and put out by pneumatic, stable and quickly.1. PLC controller 2. Touch screen type input data 3. No machine halt change data 4. Automatic paper-feeding, fold, counting, stacking